- (Flexowell® is a registered trademark of ContiTech Transportbandsysteme GmbH; licensed by ContiTech)

- While slopes of 50 – 75° are common, Flexowell can operate at 90° slopes (vertical).

- Conveyors can be easily adjusted to the factory layout.

- Inclined transport saves space in the factory

- Lateral stiffness and pressure rollers allow the belt to easily adapt to changes in tilt angle

- The edge beam is designed in a wavy shape so the conveyor belt edge is not necessary.

- Can be used with small diameter pulleys

Product Catalog

Menu

Flexowell® Conveyor Belts

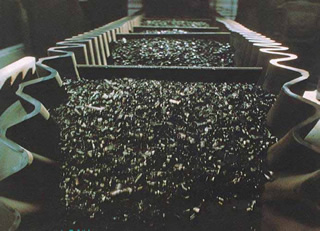

FLEXOWELL® conveyors are efficient bulk material transport solutions, capable of operating horizontally, inclined and vertically, meeting transport needs with gradients up to 90°.

Features

Inclined conveying for raw materials in iron and steel plants, cement plants, mines, quarries, waste and wastewater treatment facilities, paper mills, coal plants, wood chip plants, etc.

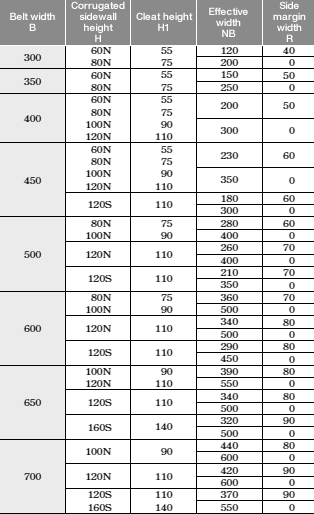

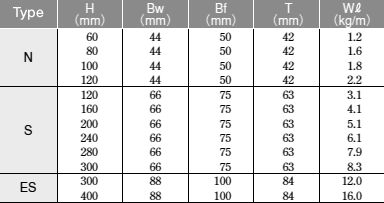

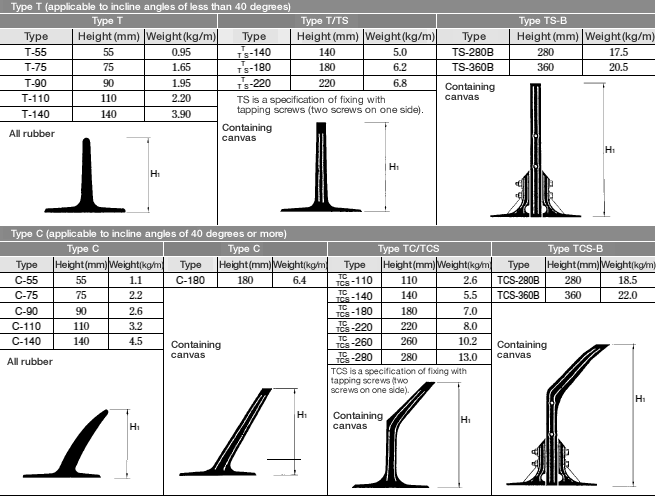

Standard specifications

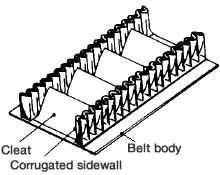

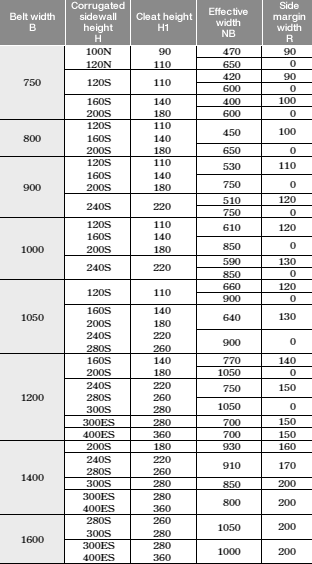

The Flexowell® Conveyor Belt consists of a belt body, corrugated sidewalls, and cleats. The following shows the standard combinations of the three parts.

*Unit: mm

Note:

– We can manufacture other belt widths than the above as well.

– For NB or Type ES, the standard range is in the units of 100 mm.

Please consult with us.

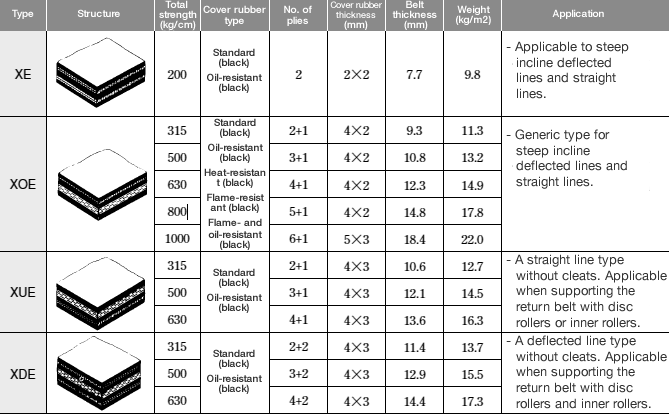

Belt body

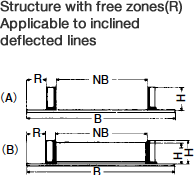

The belt body, which is the base of the Flexowell Belt Conveyor Belts, has vertical flexibility for fitting with pinions and horizontal rigidity for flexible deflection with support on the free zones.

(Note 1)About cover rubber types Heat-resistant (black): This type is medium-temperature-resistant and applicable to conveyed material temperatures of 100°C or lower and belt surface temperatures of 70°C or lower (ambient temperatures of 60°C or lower).

(Note 2) For a total strength of 1250 kg/cm (1250 N/mm) or more, we provide a different design. Please contact us.

(Note 3) The belt body has square sides as a standard. However, we can also manufacture a type with side rubber (round sides).

(Note 4) We can also manufacture other cover rubber thicknesses than the above. Please consult with us.

(Note 5) The flame- and oil-resistant types are for measures against fire at oversized trash disposal centers.

They are applicable to steep incline lines after a crusher. (Flame-resistant performance: Equivalent to those that passed the JIS flame-resistant test).

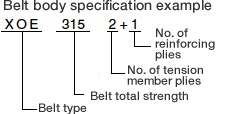

Symbols for belt type specification

– X: special canvas

– O: special canvas used for the top

– U: special canvas used for the backside

– D: special canvas used for both sides

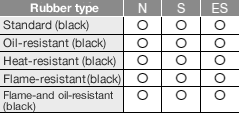

Corrugated sidewall

– N: for light load (all rubber type)

– S: for medium load (containing canvas)

– ES: for heavy load (containing reinforcing canvas)

The circle mark indicates the scope of application of the respective rubber type by corrugated sidewall type.

Contact Us

Product Catalog

Menu